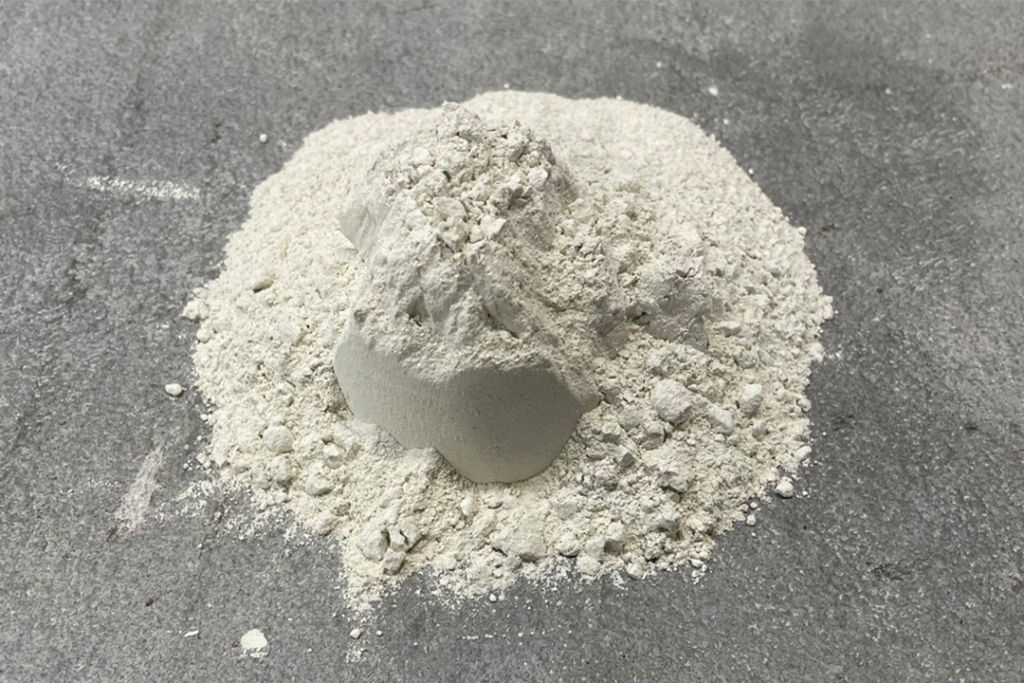

DRILLING MUD

High yield Wyoming sodium bentonite produces a high performance, multi-purpose drilling fluid. Our products are fast mixing, and provide excellent viscosity, gel strengths, soil sealing, hole cleaning and lubricity.

Applications/Functions:

- Horizontal Directional Drilling

- Slurry Wall and Slurry Trenching

- Tunnel Boring and Bored Pilings

- Soil Sealing and Pond Lining

- Other Hydraulic Barrier Applications

Advantages:

- Easy to mix and yields a multi-purpose, high viscosity slurry

- Provides a stable slurry without separation for prolonged periods

- Compatible with drilling mud additives, cement and other construction additives

Availability: High Yield bentonite is produced in locations in Wyoming and can be purchased through Bentonite Performance Minerals, LLC (assigned reseller Drilling Mud Direct, LLC.). We can also supply a full range of additives. Ship them on the same truck with your high yield bentonite products to save money. Contact us for details.

DRILLING FLUID ADDITIVES

- Fluid Loss Control/Polyanionic Cellulose-L

- Fluid Loss Control/Polyanionic Cellulose-R

- Clay Control

- Drilling Detergent

- Bore/Mud Lubricant

- Liquid PHPA (Polymer)

- Soda Ash (pH Control)

- Xanthan Biopolymer

- Swelling LCM Polymer

- LCM – Hole Sealing Aid

- HDD One Sack

Please contact your DMD salesperson for more information about

any of the drilling fluid additives we offer.

SOLIDIFICATION

Bentonite is a clay-like mineral that is composed of smectite and montmorillonite. These minerals are hydrated aluminium silicates, which swell in water to form a gel-like material. Bentonite is used as a soil conditioner, as it increases the water-holding capacity of soils, and it is also used as a sealant in geotechnical applications.

Bentonite has been used as a solidification product for treating wastewater. In this application, bentonite is mixed with the wastewater to form a gel. The gel traps the pollutants in the wastewater and prevents them from escaping into the environment. Bentonite can also be used to solidify oil spills.

Bentonite has many advantages over other solidification products. It is non-toxic, environmentally friendly, and can be an economical solution. It can also be used in a variety of applications, including soil improvement, wastewater treatment, and oil spill remediation.

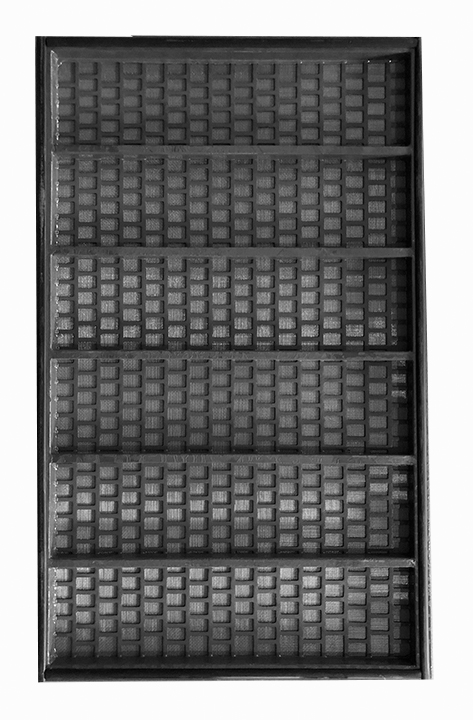

SHAKER SCREENS

HIGH QUALITY SHAKER SCREENS

Mud shaker screens are an important part of the drilling mud system. They play a critical role in keeping the drilling mud clean and free of solids.

There are several different types of mud shaker screens, each with its own advantages and disadvantages. The most common type is the vibrating screen. Vibrating screens use vibrations to move the solids through the screen. This type is efficient at removing small particles, but can be less effective at removing larger particles.

Another type of mud shaker screen is the rotating screen. Rotating screens use a rotating drum to move the solids through the screen. This type is effective at removing both small and large particles, but can be less efficient than vibrating screens at removing smaller particles.

The final type of mud shaker screen is the perforated plate screen. Perforated plate screens use a series of plates with holes in them to remove the solids from the drilling mud. This type is very effective at removing small particles, but can be less effective at removing larger particles.

Choosing the right type of mud shaker screen is critical for maintaining a clean drilling mud system. Consider the size and type of solids that need to be removed and choose a screen that is best suited for those requirements.

DMD combines its best in class shaker screen product with unmatched customer service. As with all of our products, you can trust DMD to help keep your job site running as efficiently as possible. Please contact your DMD salesperson for more information about any of the shaker screens we offer.

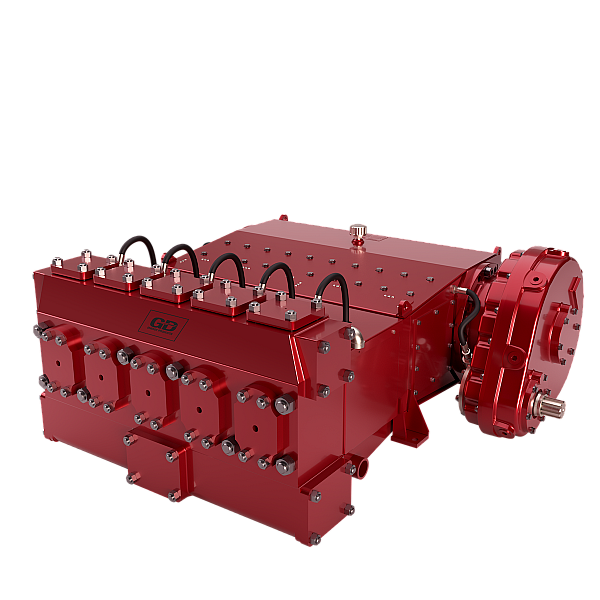

PUMPS & EQUIPMENT

TOOLS OF THE TRADE

HDD drilling pumps

If you’re looking for a powerful and reliable drilling pump, an HDD drilling pump is a great option. These pumps are specifically designed for use with high-density drilling rigs, and they offer superior performance and durability.

HDD drilling pumps are available in both electric and hydraulic models, so you can choose the option that best suits your needs. Electric models are typically smaller and lighter, making them easier to transport, while hydraulic models offer more power and can handle heavier loads.

whichever model you choose, HDD drilling pumps are built to last. They feature heavy-duty construction that can withstand the tough demands of day-to-day use, and they come with a range of features that help make operation easier and more efficient.

For more information on these pumps and the options available, contact the experts at DMD.

TESTING EQUIPMENT & MORE

ALWAYS ON THE JOB

When it comes to drilling mud additive chemical testing, there are a few key factors that need to be taken into account. The first is the type of drilling mud that is being used. In general, there are three main types of drilling mud – water-based, oil-based, and synthetic-based. Each type of drilling mud has its own set of benefits and drawbacks, so it’s important to choose the right one for the job.

The second factor to consider is the specific additives that are going to be used in the drilling mud. Some additives are designed to improve the stability of the drilling mud, while others are intended to help keep the drill bit cool. It’s important to test each additive separately to determine how it will affect the drilling process.

Finally, it’s important to test the final mixture of additives and drilling mud. This involves combining all of the ingredients together and running a series of tests to see how they work together. By doing this, it’s possible to fine-tune the mixture so that it works best for the specific job at hand.

CONTACT DMD

HAVE QUESTIONS? WANT TO LEARN MORE?

Please fill out the form below and one of our reps will contact you.